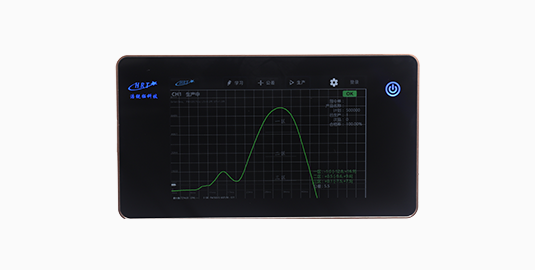

Intelligent stress detection system

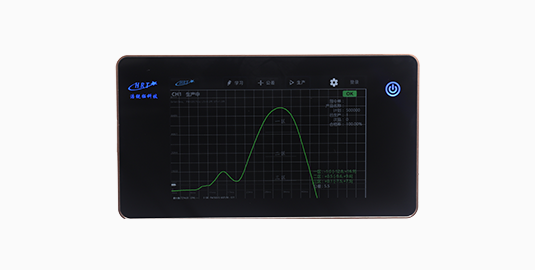

Intelligent Stress Management System (Terminal crimp Failure Detection System) is the world's first pressure management device based on Deep Learning AI technology.

Product Video

Global unique, 100 million level big data pre-training

Application Function

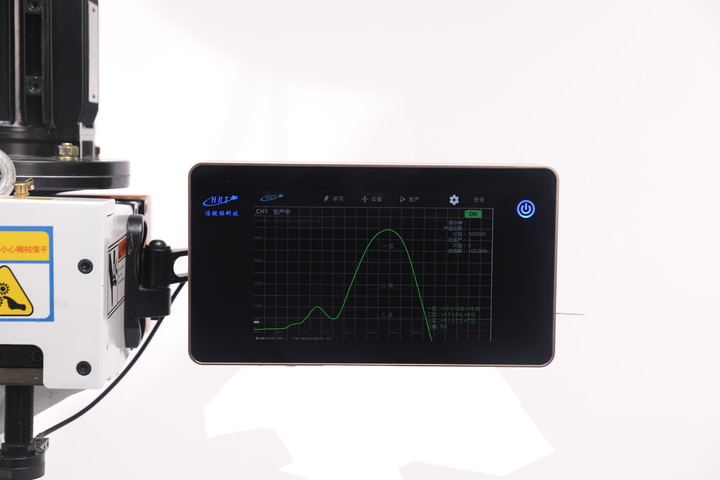

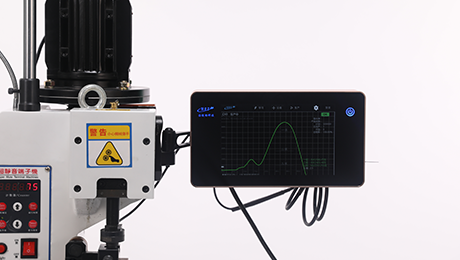

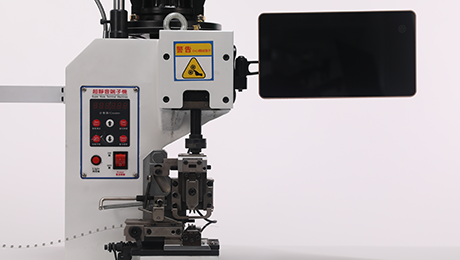

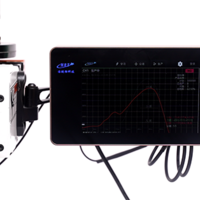

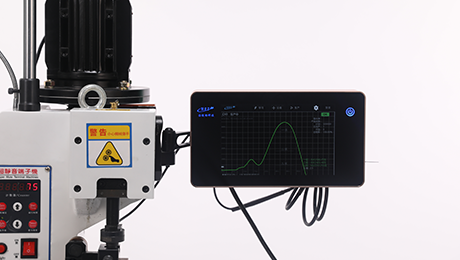

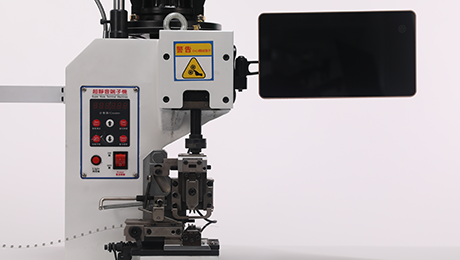

Terminal crimp stress testing equipment

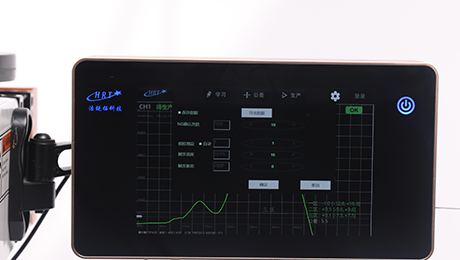

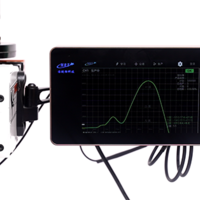

Stress testing

Installed on the terminal machine, it is used to detect pressure changes during terminal crimping in real time and screen defective products such as deep and shallow crimping, broken core wire, and missing crimping.

Core Advantage

AI algorithm, more accurate, more simple

Proprietary technology

Hundred million terminal crimping big data, AI deep pre-learning, error correction and recognition ability.

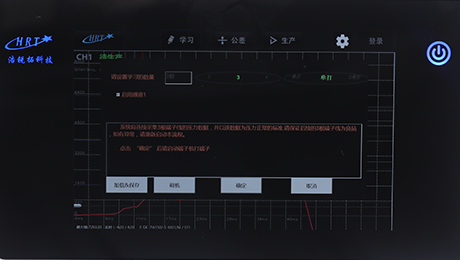

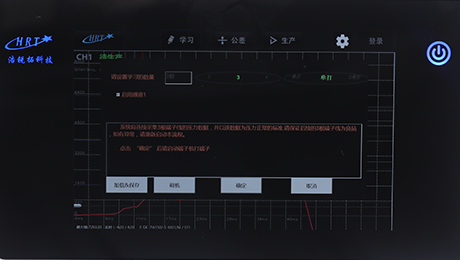

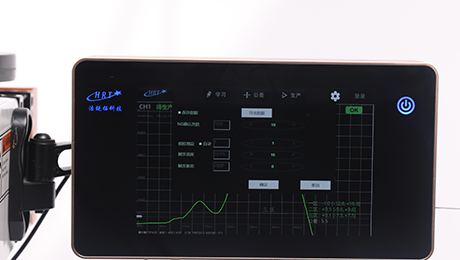

Easy difficulty

Three steps to complete the good product standard collection and input, intelligent real-time detection terminal crimping bad.

Debug mould

Scan the code to obtain the parameters recorded in the bar code/two-dimensional code, no need to change the mold machine.

High-end configuration of the computer

2/4-core processor, HD display, 1-2G RAM, 8-32GB hard disk.

Multifunction

Support WiFi and 3/4/5G, provide complete reports, cloud services and monitoring management.

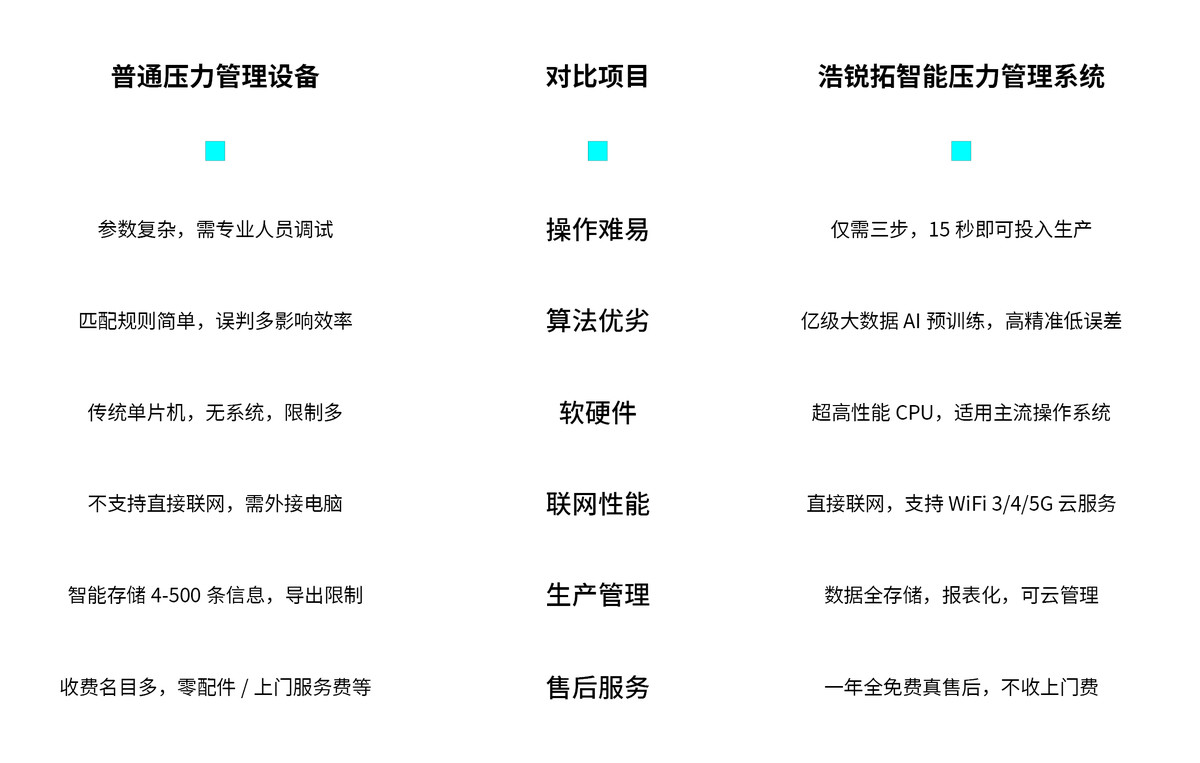

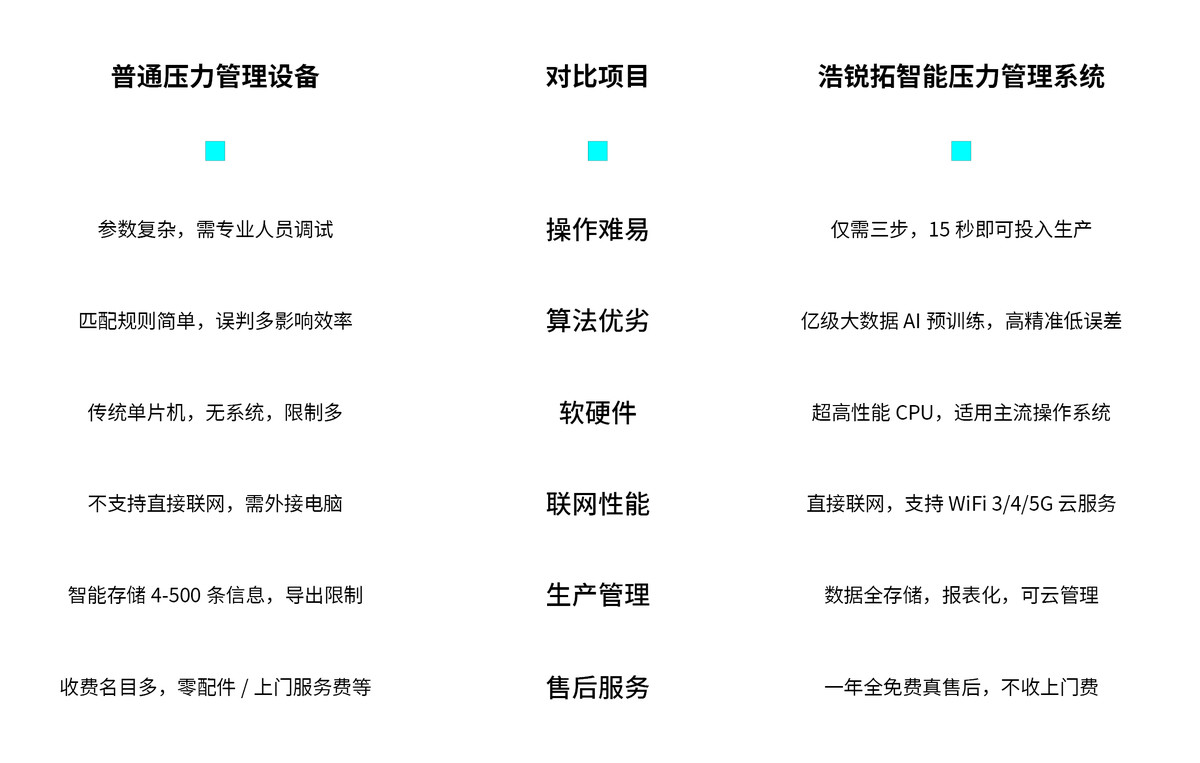

Comparison to competitive products

Better performance than conventional, more accurate, fewer false positives

Model number

Select according to demand, make the best use of materials

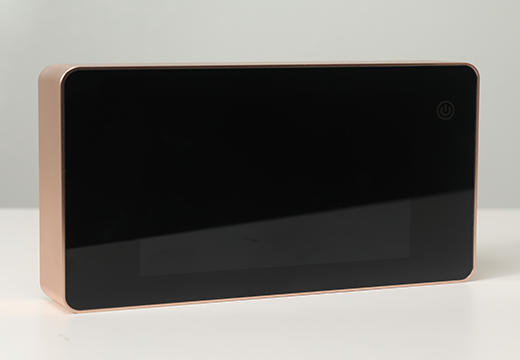

Model No.:HRT-CFM1S/02S

Detection range: ≥ Line 26

Detection algorithm: direct expansion algorithm

Hardware configuration: 2-core 1.83GHzCPU, 1 GB memory, 8 GB hard disk

Sensing mode: Supports wall-mounted sensing

Display screen: 7 inches, 1280*800

More functions: WIFI, report, MES interface, etc.

Model No.:HRT-CFM01/02

Detection range: ≥ Line 32

Detection algorithm: artificial intelligence algorithm

Hardware configuration: 4-core 1.83GHzCPU, 2 GB memory, 16 GB hard disk

Sensing mode: Supports wall-mounted sensing, punch sensing, and baseboard sensing

Display screen: 8 inches, 1920*1200

More functions: even plan method, intelligent range, report, MES interface, etc.

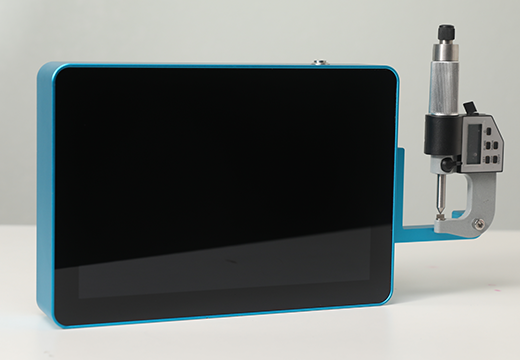

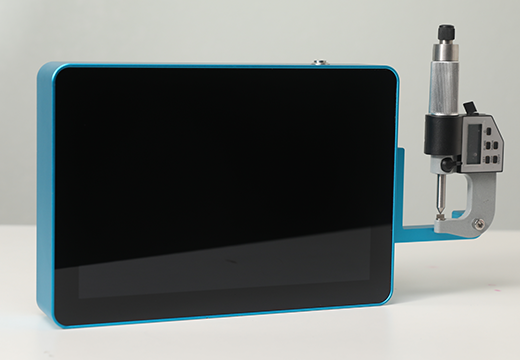

Model No.:HRT-CFM01PRO/02PRO

Detection range: ≥ Line 32

Detection algorithm: artificial intelligence algorithm

Hardware configuration: 4-core 1.83GHzCPU, 2G memory, 32GB hard disk

Sensing mode: Supports wall-mounted sensing, punch sensing, and baseboard sensing

Display screen: 10.1 inch, 1920*1200

More functions: micrometer, even planning method, intelligent range, report, mold tolerance, blade management, MES interface, scanning code work order, etc.Request a demo/trial now

Personally experience can feel the product performance.

More Discovery

Discover more useful wire harness quality inspection equipment

Intelligent terminal crimping stress management system

With 100 million level terminal crimp big data pre-training product series

Intelligent terminal tension detector

Multifunctional and real-time automatic tension data recording product linE

Intelligent wire harness sequence detector

Harness sequence detection market share of more than 90% of the product series

Intelligent terminal cross section analyzer

More than 95% of the links to achieve the full automation of the product series

Product recommendation:

Intelligent pressure management system

intelligent tension testing machine

intelligent conductivity tester

wire harness sequence detector

Auto fuse box detection

terminal press appearance detection

optical fiber sequencing detector

General Manager Email: CEO_Office@haorui-tech.com Have comments or suggestions? You can send E-mail to contact the general manager's office. We will reply within 24 hours on weekdays.

© 2019 Shenzhen Haorituo Technology Co., LTD. All Rights reserved