Terminal crimp failure detection system

Coating

Shallow beating

Fly silk

deformation

Broken copper wire

...

In the wiring harness production process

Have you ever been troubled by the crimping quality problems?

An overnight rework at a customer's factory?

Often lead the team to do the review?

A fine of 2000 for a wrong harness?

Do you calculated that because of quality problems,

How many fines have you paid? How many clients did you lose?

Some thoughts

What differentiates you from your peers?

Have you deliberately created differentiation?

You don't create differentiation

Do not improve quality

But your peers won't be idle

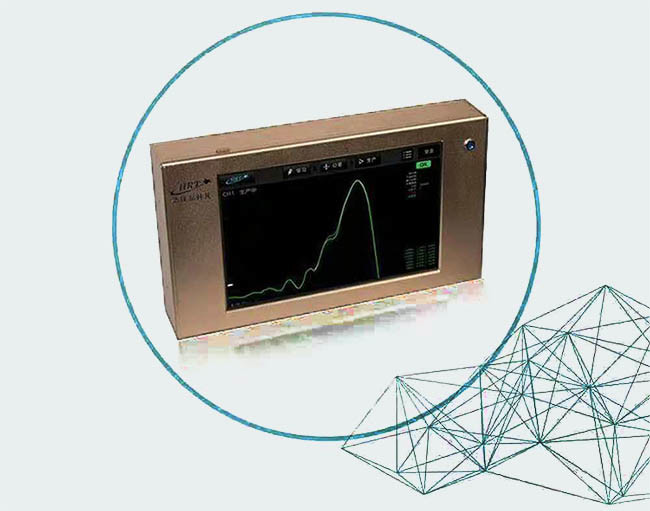

HRT-CFM Intelligent pressure management system(Poor terminal crimping detection system)

Installed on the terminal machine

Detection terminal pressing deep, shallow, broken core and other NG problems.

1. There is no need to set parameters and users need no training

2. Support for native wireless Internet of Things

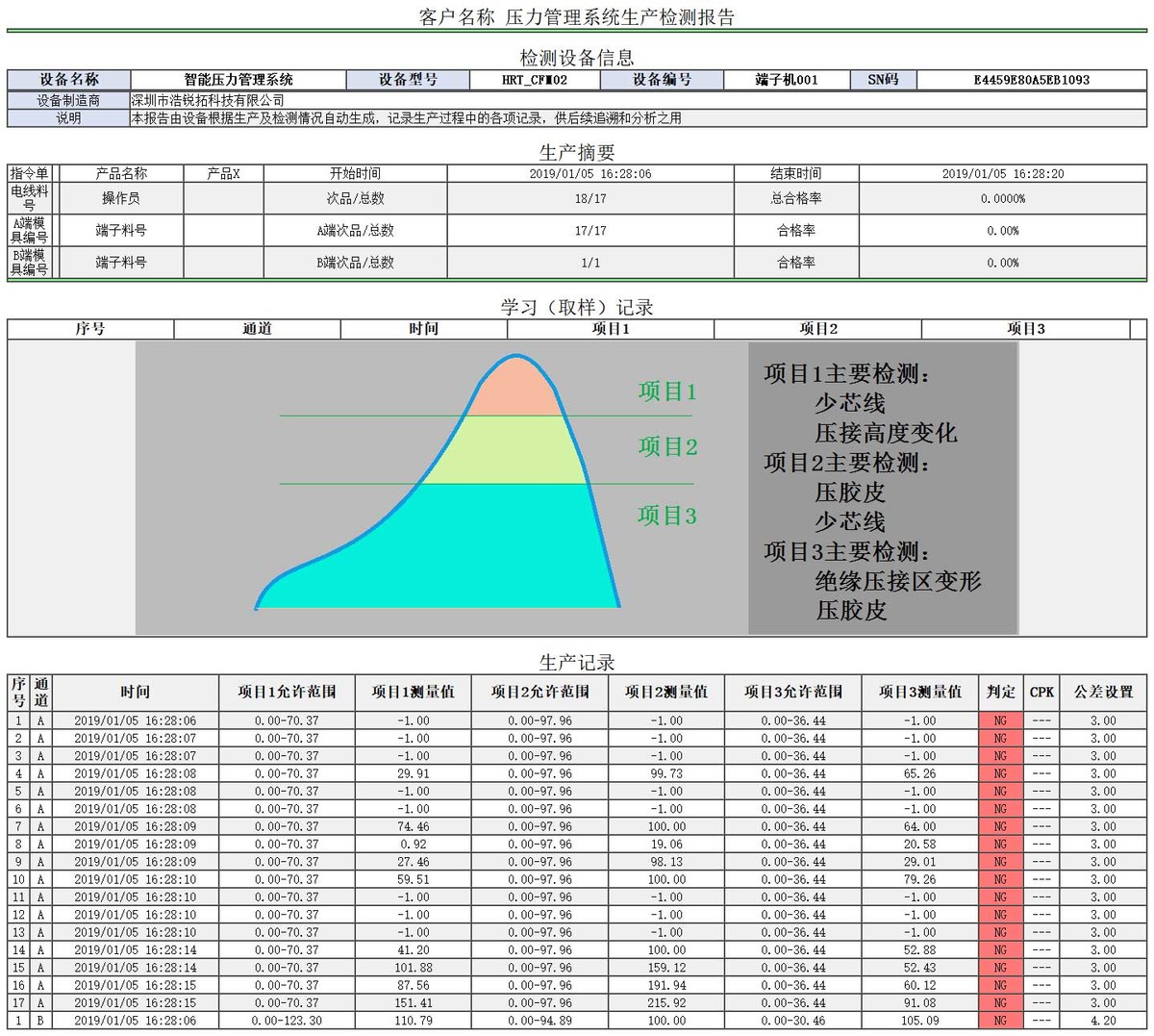

3. All materials, machines, operators and test results can be traced back when pressed

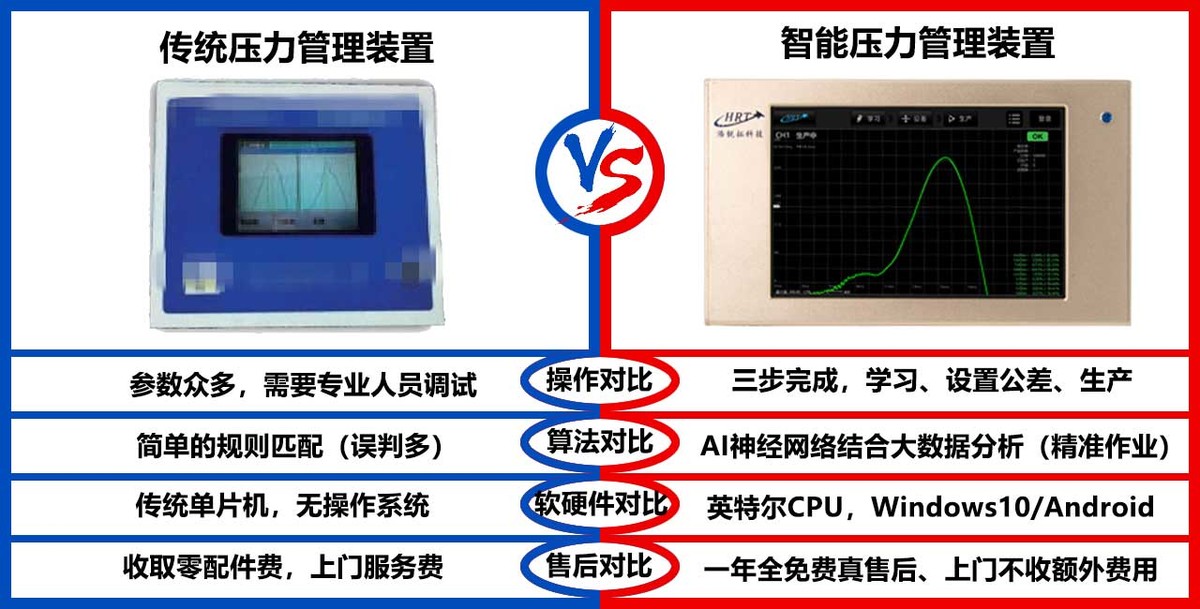

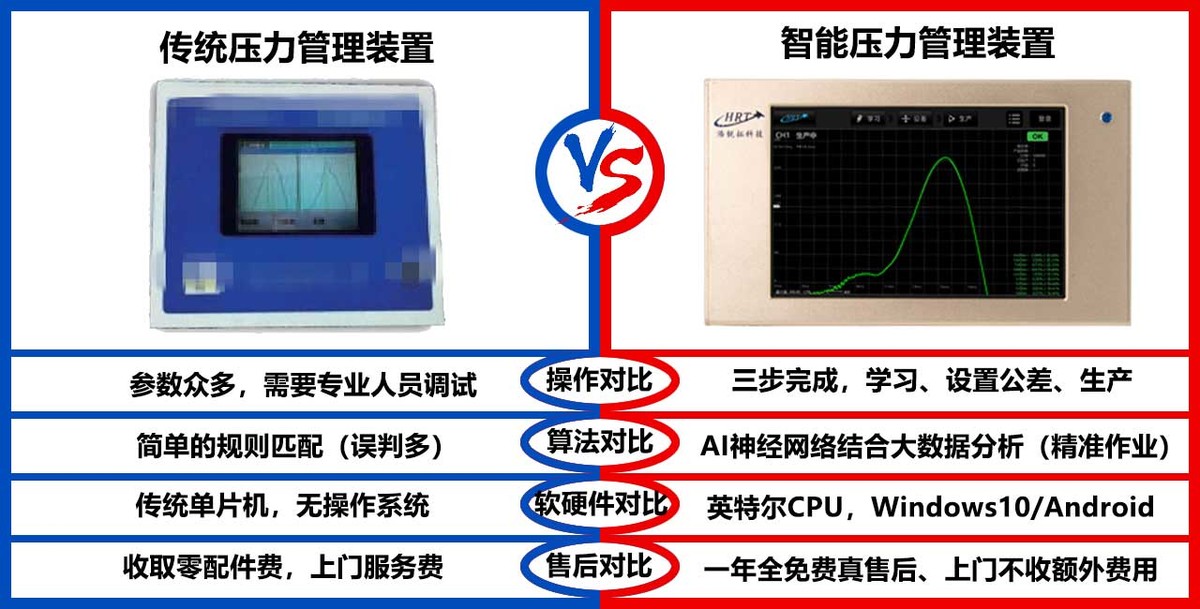

Intelligent pressure management system: It is used for real-time detection of terminal crimping quality equipment. Compared with traditional pressure management devices, it provides better detection performance and intelligence through AI artificial intelligence technology and Internet of Things technology, and provides basic support interface for digital factories!

Get product information/quotes

Working principle: Combining big data analysis and neural network AI technology, through billions of times of pressure waveform detection of good terminals, find out the commonality of pressure waveform of good terminals, and help to find out defective terminals (coating, deep crimping, shallow crimping, flying copper wire, broken copper wire, etc.) in the production process.

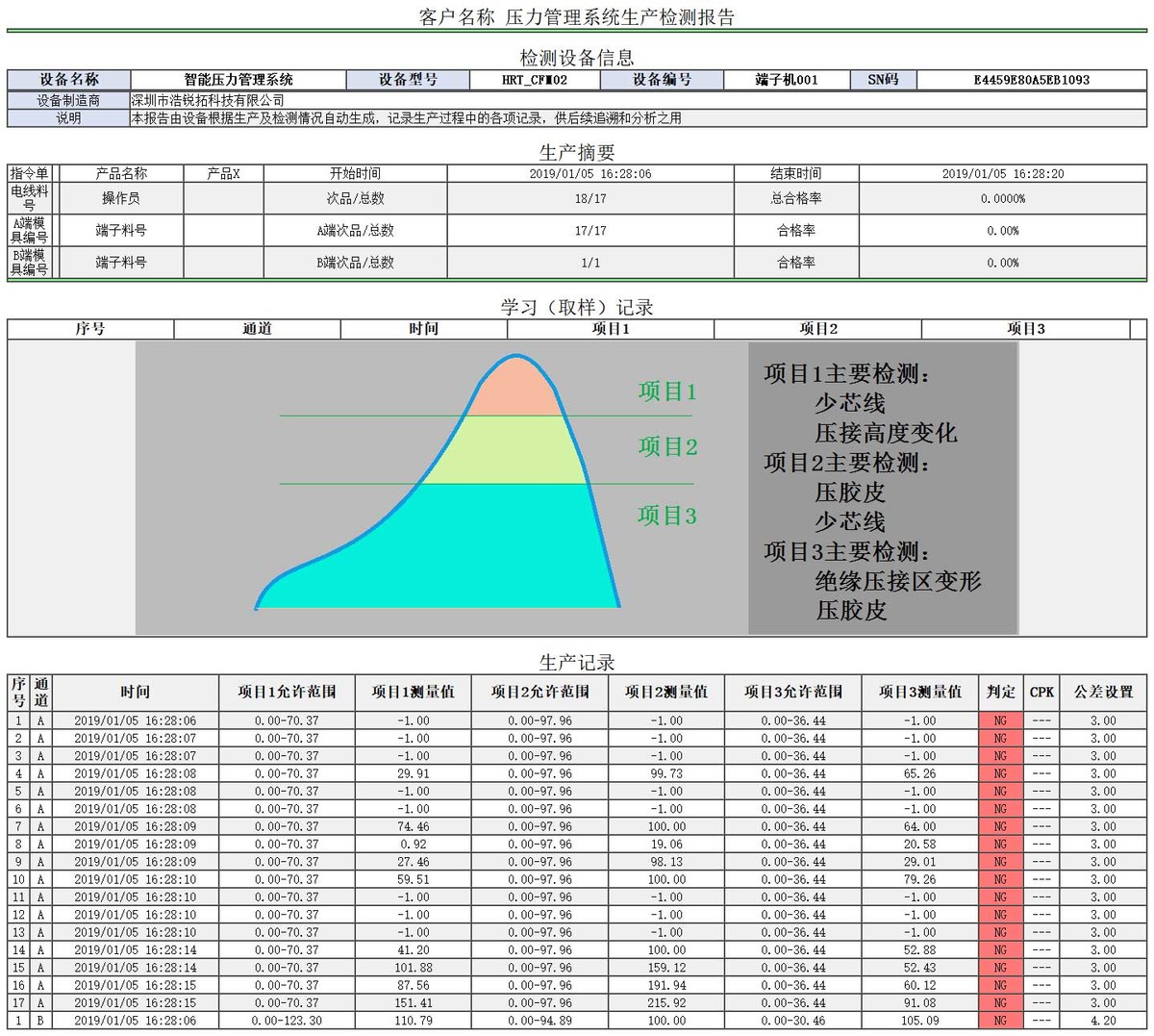

Each terminal cable can provide a quality inspection report to provide the customer with a real basis

Get product information/quotes

Product recommendation:

Intelligent pressure management system

intelligent tension testing machine

intelligent conductivity tester

wire harness sequence detector

Auto fuse box detection

terminal press appearance detection

optical fiber sequencing detector

General Manager Email: CEO_Office@haorui-tech.com Have comments or suggestions? You can send E-mail to contact the general manager's office. We will reply within 24 hours on weekdays.

© 2019 Shenzhen Haorituo Technology Co., LTD. All Rights reserved